Equipment introduction:SLG65—C type double-screw extruder technical parametersScrew diameter: Φ65mmScrew speed: 0~250rpmzProcessing capacity: 80~120kg/hTemperature control range: 0~399cMotor power: 22kwMachine center height: 1020mmDimensions: 2400×960×1800mmSLG65-C type double-screw puffing machine is a puffing food equipment suitable for my country’s national conditions, developed by using the international advanced double-screw extrusion puffing technology, combined with our company’s rich experience in puffed food technology research for many years.Host FeaturesThe host adopts a stable and

Contact Now

EQUIPMENT INTRODUCTION:Using the international advanced twin-screw extrusion technology, combined with our company's rich experience in puffed food technology research for many years, we have developed a puffed food equipment suitable for my country's national conditions. Applicable to a wide range of raw materials,corn, rice, soybean, black rice, mung bean, buckwheat and other whole grains can be used as raw materials.EQUIPMENT ADVANTAGE1.

Contact Now

Main features of VINCI single screw extruder 1. The feeding, rotary cutting and main drive all adopt the frequency conversion speed regulation system, which has strong power and stable operation. 2. The extrusion system is equipped with six sets of temperature control and automatic cooling devices, and the temperature control is accurate and stable. 3. Suspended mold (knife) set seat, which can improve the replacement speed of molds and knives. 4.

Contact Now

Equipment introductionSLG85-A large-scale twin-screw extruder is a puffed food equipment developed by using foreign advanced twin-screw extrusion technology and combined with our company's rich experience in puffed food technology research for many years.The equipment adopts stable and reliable frequency conversion speed regulation system and precise pressure sensing system, which makes the operation more convenient and accurate. The spiral part adopts a specially designed screw structure such as two co-rotating, double-ended arc grooves and kneading blocks.

Contact Now

Main features of SLG85-D twin-screw extruder 1. The feeding, rotary cutting and main drive all adopt the frequency conversion speed regulation system, which has strong power and stable operation. 2. The extrusion system is equipped with six sets of temperature control and automatic cooling devices, and the temperature control is accurate and stable. 3. Suspended mold (knife) set seat, which can improve the replacement speed of molds and knives. 4.

Contact Now

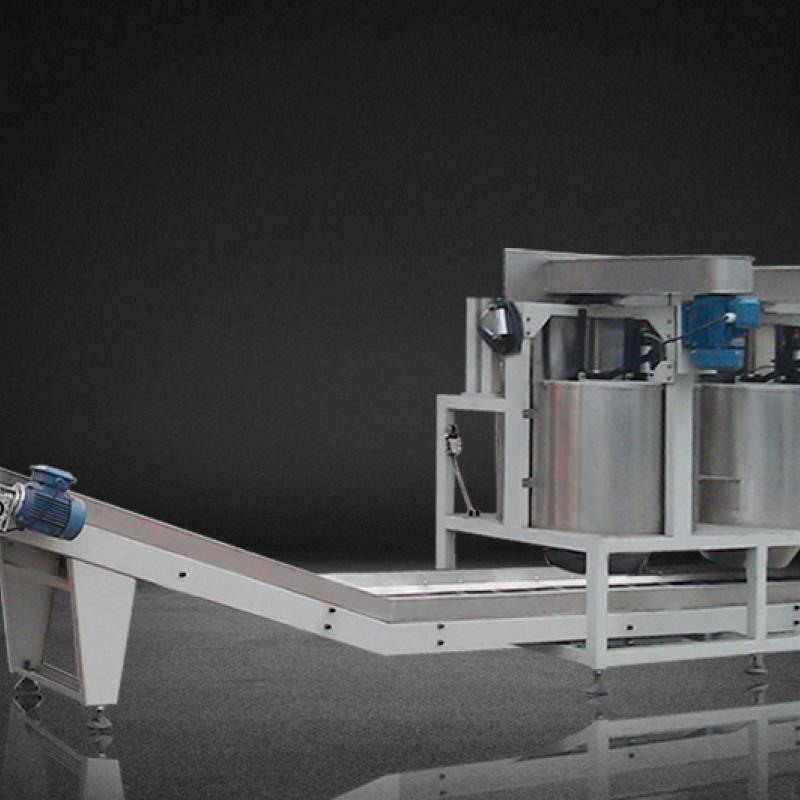

Equipment overview:This machine is a high-temperature baking equipment, and the working temperature can reach 350 °C. When working, the material first enters the lower hopper of No. 1, and then goes through the vibrating feeder of No. 2 into the screw conveying cylinder of No. 5. The inside of the screw conveying cylinder is heated by No. 7. The fan provides the heat source, and the heat is continuously circulated by the serial number 8 circulating fan to make the inside of the screw conveying cylinder reach 200-350 °C.

Contact Now

1. The feeding, rotary cutting and main drive all adopt the frequency conversion speed regulation system, which has strong power and stable operation. 2. The extrusion system is equipped with six sets of temperature control and automatic cooling devices, and the temperature control is accurate and stable. 3. Suspended mold (knife) set seat, which can improve the replacement speed of molds and knives. 4. Double helix forced feeding and photoelectric eye tracking can make the material added evenly and prevent material shortage. 5.

Contact Now

Equipment introductionThis machine is the supporting equipment for the pasta host. This machine is required when the main engine produces traction cut. Both straight and oblique cuts can be produced. The machine has reasonable equipment, beautiful appearance, and is equipped with an advanced frequency conversion speed regulation system.Schematictechnical parameter:Cut off drive power: 0.55KWTraction drive power: 0.37KWDimensions: 2300×830×1100mmProduction capacity: with the hostWeight: 250kgInstallation and corresponding adjustment1.

Contact Now

The nutritional rice production line developed by our company takes Rice noodles as the main raw material, and can selectively fill a variety of vitamins and minerals, such as vitamin B, vitamin C, vitamin A, etc. according to production needs. Extrude the shape of rice grains through a twin screw extruder, then dry to the required moisture content, and cook for 5-10 minutes before consumption. The extrusion puffed rice production technology developed by our company makes it possible to strengthen trace elements in rice.

Contact Now

Shandong Dayi Machinery Co., Ltd has many types of extruders,they are high degree of automation. The dog food production line equipment can realize one-key start of the host, real-time data storage, real-time monitoring, alarm reminder and other functions.Dog Food Production Line Design: Designed by 3D software, analogue simulation, and it is tested by computer automaticall, to ensure the require-ments of design precision.Concept: Modular function, humanized system, diversified applications are always our pursuit.

Contact Now

The core filling snack production line developed by our company is an advanced production line, which uses advanced co extrusion technology to extrude two kinds of products with different texture and taste on a twin-screw host at the same time. It can process a variety of raw materials at the same time, such as Rice noodles, syrup, fruit paste, etc., and process them into a variety of sandwich rice fruit products, such as McChicken pieces, cocoa desserts, sandwich rice fruit, maishao, banana crisp, rice fruit, etc.

Contact Now

Vegetarian soye meat making machine is made of low temperature defatted soy flour, wheat protein, soybean and remoted protein as the primary uncooked materials, and produced thru mixing, cooking, and extruding inside the double-screw extruder underneath high temperature and high pressure. the fiber soy protein is in strong muscle fiber structure with excessive tenacity that may maintain suitable water and oil absorption capacity, so it may be extensively used in meat, speedy meals, instant meals, fillings as vegetarian meat.

Contact Now

The puff snack production line adopts advanced extrusion technology to produce puffed food, producing various popular puffed sandwich foods on the market, such as wheat flavored chicken nuggets, sandwich rice fruits, sandwich rice crisps, rice fruits, banana crisps, cocoa desserts, wheat roasting, cheese balls, etc. Nutritional powder, cereal Congee and puffed snack food of various shapes can be produced by changing molds and auxiliary equipment.

Contact Now

Meat analog make system is designed and produced with our rich evaluations on food extruder enterprise for over 20 years. it adopts nonfat low temperature soya bean meal as most vital raw material to supply all varieties of textured protein food, that is nutritional and resultseasily absorbed with the resource of human frame. such soya protein meals looks like real muscle meat and mastication. textured soya protein meals is extensively appied to many industries, together with can food, sesoning meals, ham, cooking, and so forth.

Contact Now

This process line adopts advanced share extrusion technology, which can extrude products with different textures and tastes out of double- screw extruder at the same time. It can produce a variety of core-filling food which are popular in the market, such as fragrant chicken, core- filling rolls, etc. It can also produce nutritional powder, grain gruel and many other snacks by changing moulds and assistant equipments.

Contact Now

Fish food process line endues pet food with the amount of nutrition, digestible structure, novel shape, and unique taste to meet with the needs of modern market. The dog chewing food is extruded into a variety of shapes such as stick, bone, etc.

Contact Now

Golgappa snack making machine is newly designed and produced with foreign places superior era. it has stepped forward the dangers of import device together with huge funding and immoderate manufacturing value. this line uses corn starch, wheat flour, potato starch as materials to deliver"bugles", "net", "potato chips" and hundreds of various 3-d compound extrusion meals. this line may be in comparison with those import equipments. below the equal capabilities, its rate is pleasant one tenth of that of import machine.

Contact Now

This technique line is newly designed and produced with foreign places superior technology. it has progressed the risks of import device which consist of large funding and excessive production charge. this line makes use of corn starch, wheat flour, potato starch as substances to supply"bugles", "internet", "potato chips" and hundreds of numerous 3-d compound extrusion meals. this line can be in contrast with those import equipments. underneath the equal features, its price is satisfactory one tenth of that of import machine.

Contact Now

Breadcrumb is specifically used for fried beefsteak and bird as frying dressing. this line is specially designed and evolved to perform from the fabric to very last shaping robotically with much less manpower, with out waste,lower production price, and better manufacturing performance.

Contact Now

This Double-screw fried wheat flour snack processing line uses double screw extruding technique to replace the traditional steam booling process with high efficiency and no pollution without a boiler. The raw material can be total whear flour, or mixing with corn powder, rice powder, or others. By changing the moulds, the products can be in different shapes. After fried and flavored, the final snacks will be crispy and tasty. This line has features of continuous working, stable performance, and reasonable design.Schematic diagram of production line

Contact Now

Overview:The equipment is reasonable in design, easy to operate, and low in price. It is also equipped with a chassis for placing the receiving box and discharging conveying.

Contact Now

Fruit and vegetable food production line generally consist of the following food processing equipment.1. Fruit elevatorHigh lift machine used for fruit cleaning and conveying to crushing station after fruit picking.2. Fruit washerUsed for ordinary fruit cleaning and preliminary selection and carrot cleaning degree of high requirements of fruit cleaning.Step 3: CrusherHammer crusher and squirrel cage crusher are used for the initial crushing of fruits and vegetables.4.

Contact Now

This system line is newly designed and produced with foreign superior generation. it has advanced the dangers of import device together with large funding and high manufacturing price. this line uses corn starch, wheat flour, potato starch as materials to produce"bugles", "web", "potato chips" and lots of other three-D compound extrusion food. this line can be compared with the ones import equipments. below the same features, its fee is most effective one tenth of that of import equipment.

Contact Now

This process line is newly designed and produced with foreign advanced technology. It has improved the disadvantages of import equipment such as large investment and high production cost. This line uses corn starch, wheat flour, potato starch as materials to produce"bugles", "web", "potato chips" and many other 3D compound extrusion food. This line can be compared with those import equipments. Under the same functions, its price is only one tenth of that of import equipment.

Contact Now