SLG85-A Host

The equipment adopts stable and reliable frequency conversion speed regulation system and precise pressure sensing system, which makes the operation more convenient and accurate.

Equipment introduction

SLG85-A large-scale twin-screw extruder is a puffed food equipment developed by using foreign advanced twin-screw extrusion technology and combined with our company's rich experience in puffed food technology research for many years.

The equipment adopts stable and reliable frequency conversion speed regulation system and precise pressure sensing system, which makes the operation more convenient and accurate. The spiral part adopts a specially designed screw structure such as two co-rotating, double-ended arc grooves and kneading blocks. It has the characteristics of self-cleaning function, high pushing efficiency and good shearing homogenization effect. The equipment has high output, reasonable design, high degree of automation, convenient operation, small footprint, energy saving, and small processing loss, and can be deeply redeveloped and applied to grains. The extrusion equipment belongs to the domestic advanced level. Its development and production fill the gap of domestic large-diameter twin-screw extruding equipment.

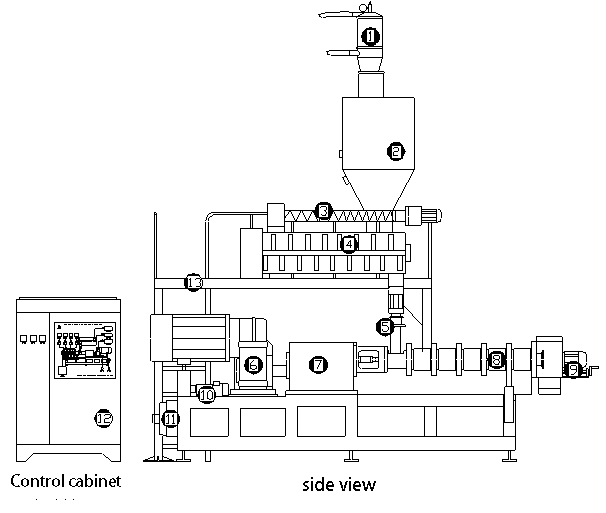

Equipment structure:

1 Vacuum feeder 2 Storage barrel 3 Feeding device 4 Stirring device 5 Forced feeding 6 Driving device 7 Distributing box 8 Extrusion cavity 9 Rotating cutting device 10 Lubricating device 11 Oil cooling device 12 Control cabinet 13 Platform

As shown in the figure, the SLG85-A host is mainly composed of 11 parts. First, the raw materials are mixed and added to the storage barrel through the vacuum automatic feeder, and then evenly fed into the stirring device through the feeding device. The raw materials are transported to the extrusion cavity. There are heating and cooling devices outside the extrusion device to control the constant temperature required for the raw materials. The screw in the extrusion device is controlled by a strong drive device and a reliable distribution box to ensure the stability of the equipment. The distribution box is a key part of the equipment, and it is forced to be lubricated by the lubricating device and the oil cooling device to ensure the operation! The raw materials are mixed, kneaded in the extrusion cavity, extruded into semi-finished products at high temperature and high pressure through a specific die, and finally cut into qualified products by the rotary cutting device.

All the power of this equipment is controlled centrally by the control cabinet; the conditioner and the storage device are installed on the workbench, which makes the equipment compact and easy to operate!

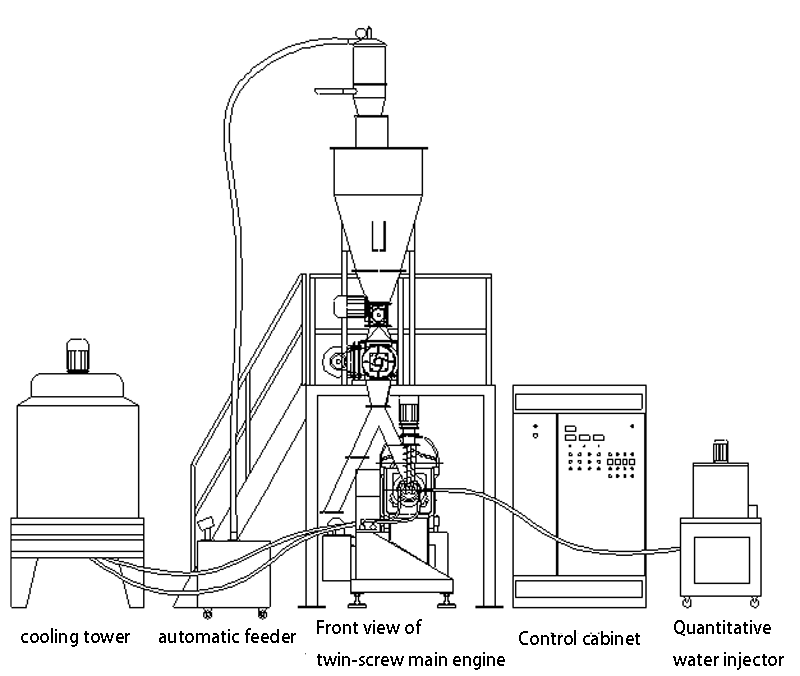

In addition to most of the 13 parts in Figure I, the SLG85-A mainframe also needs a cooling water tower and a quantitative water injection machine to ensure the normal operation of the mainframe. The specific arrangement and access are shown in the figure!

Equipment principle

The main parts of the twin-screw extrusion system are the screw and the screw sleeve. The two screws are double-headed right-handed, meshing with each other and rotating in the same direction. During the working process, the materials sticking to the screw are scraped and pushed forward. The screw is composed of 80mm, 60mm, 40mm, and 20 shear rings and kneading blocks respectively. All the threads are trapezoidal threads with a depth of 15mm. , the material increases the contact area of the sleeve, which is convenient for absorbing external heating and is conducive to the maturation of the material; Internal energy to complete material organization. The screw is connected by a spline bushing to form a whole concentric screw. This connection method has good interchangeability, convenient assembly and disassembly, and easy replacement.

The lubrication system is composed of a gear pump, an oil tank and an oil circuit, and is equipped with a special oil cooling device to force lubrication and cooling of each rotating part of the distribution box.

The main driving power in the transmission system is a specially customized FA series parallel shaft helical gear reducer, which is directly connected to a 90KW motor. The power enters the distribution box and is decomposed into two output shafts that rotate in the same direction; the helical gears Z30 and Z60 are external meshing, belonging to the triangle In the transmission system, two Z30 helical gears each carry the torque and radial thrust transmitted by the screw. The speed control system of this machine adopts frequency conversion speed control technology, which has reliable adjustment, large adjustment range and stable operation. The gear shaft in the box adopts the most advanced tandem thrust cylindrical roller bearing set to ensure the stability of the equipment.

The heating system and the barrel cooling system complement each other (matched with the water tower), as shown in the figure, the main machine consists of six barrels, including one barrel in the blanking section, one barrel in the cooling section, and the remaining four sections are cooled as shown in the figure. The water tank is equipped with copper pipes to cool the barrel. Each area outside is controlled by an infrared stainless steel heating ring. The power of each heating ring is 6KW, a total of 24KW. The temperature of each zone can be adjusted independently. The cooling is divided into five areas, four of which correspond to heating, and the solenoid valve automatically controls the entry and exit according to the heating temperature.

Technical parameter

Total equipment power: 121.12KW

Screw diameter: f85mm

Length of screw: 1960mm

Aspect ratio: 1:21

Screw speed: 0~406rpmz

Processing capacity: 500~800kg/h

Temperature control range: 0~399℃

Main drive power: 90KW

Heating power: 6×4KW

Speed regulation mode: frequency conversion speed regulation

Rotary cutting drive power: 2.2KW

Oil pump driving power: 0.37KW

Water tower drive power: 0.55KW

Oil cooling power: 0.18KW

Water tower cooling fan power: 0.12KW

Dimensions of the water tower: 900 × 900 × 1850 (mm)

Machine center height: 1200mm

Table height: 2400mm

Overall dimensions of the extrusion host: 5200×2700×5500 (mm)

ผลิตภัณฑ์ที่เกี่ยวข้อง

ข่าวที่เกี่ยวข้อง

การส่งข้อมูลสำเร็จ

เราจะติดต่อคุณโดยเร็ว ที่สุด